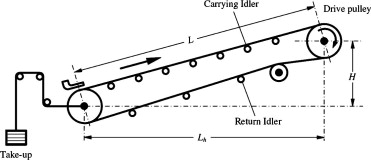

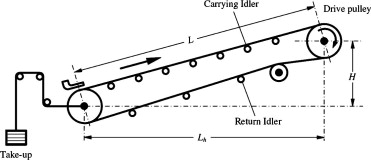

Return Idlers support the belt during the return path and meet the CEMA or ISO load requirements. The return idlers which carry the weight of the empty belt in the return side or the lower side of the belt conveyor are mostly single Roller straight idler. The mass of the return belt is the only load that return idlers are required to support. As such, Return Idler sets are spaced at two to three times the pitch of their equivalent carrying-side idler sets. Return idler sets usually have one or two rolls per idler set, for similar reasons.

we look under the conveyor bed, we will find another set of changes. This area is called the conveyor return because the conveyor is returning for another load of ore. The idlers here are called return idlers.

Return Idlers support the belt during the return path and meet the CEMA or ISO load requirements. The return idlers which carry the weight of the empty belt in the return side or the lower side of the belt conveyor are mostly single roller straight idler. The mass of the return belt is the only load that return idlers are required to support. As such, return idler sets are spaced at two to three times the pitch of their equivalent carrying-side idler sets. Return idler sets usually have one or two rolls per idler set, for similar reasons.

we look under the conveyor bed, we will find another set of changes. This area is called the conveyor return because the conveyor is returning for another load of ore. The idlers here are called return idlers.

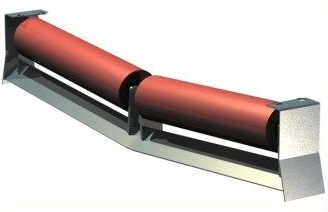

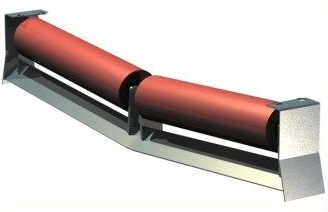

Flat return idlers comprise 1 or 2 rolls, the 1-roll design being more prevalent. In the case of a single Flat Return Idler, the idler can be mounted onto two brackets which are secured to either side of the conveyor support structure as seen adjacent.

Flat Return Idlers

Where return idler sets comprise two rolls, a support frame is required which supports the idler pair and attaches the idlers to the conveyor frame. This 2-roll design forms the return belt into a 'v' trough and these return idler sets are referred to a 'V' return idlers.

In addition to the fixed base frames for return idlers, garland-type return idlers are also available which, like their equivalent troughing idlers, are more tolerant of conveyor structure misalignment.

Size of roller: 63.5, 76.1, 88.9, 101.6, 108, 114.3, 127, 133, 139.7, 152.4, 168.3, 193.7(cm)