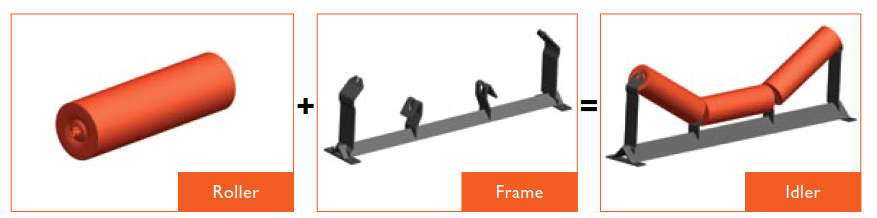

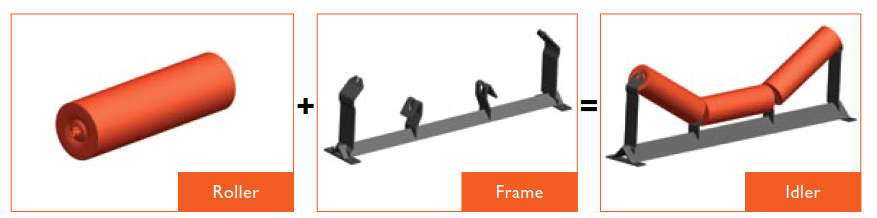

Roller is spare parts of Belt Conveyor Idler. Conveyor rollers represent the core of your conveyor system. Rollers include high quality bearings, multi-labyrinth sealing, greased and sealed for life and other critical specifications essential for high performance. For diameter range from 76mm to 219mm, for belt ranges between 450mm to 2500mm in width. Used for carrying and return idlers, recommended up to belt widths of 2000mm.

Rollers in bulk material handling are often in continuous use under extreme conditions. Several factors will go into selecting the appropriate type of conveyor rollers for your conveyor belt system, including the weight of products that will travel over the rollers and the overall path of your conveyor system. roller are used to support the conveyor belt and are installed on the groove-shape frame, groove-shape forward inclined idler frames and Transition Idler frames.

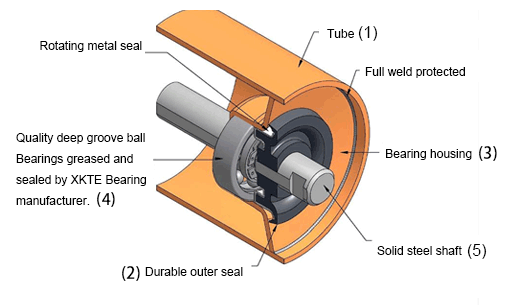

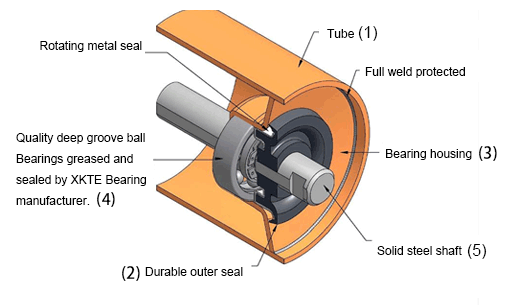

Conveyor Roller Structure

roller consist of idler roller shell, Shaft, bearing, bearing house, seals and axial clip etc.

1. Tube or shell. The Shells are made from steel tube with close tolerance ensuring smooth, Shock free and eccentricity free running with minimum dimensional run out, smallest rotating weight of rollers requires low horse power, thereby conserving power and energy due to lowest possible dynamic friction.

2. Seals should be multi labyrinth type to prevent ingress of dirt, air and moisture. The outer seal should be corrosion resistant.

3. Bearing housing are formed from strip steel deep pressed in automatic presses machine, this tolerance allowing a perfect match between the bearing and the relevant parts of the sealing.

4.Bearing. Large clearance C3/C4 serials deep groove ball bearings, reinforced cage with big rivet, thick inner ring and outer ring. usually use double sealed structure to improve the water and dust proof ability.

5. SHAFT: Shaft is formed from cold drawn round bar and calibrated to ISO to ensure precise assembling of bearing.

Main ball Bearing For Conveyor Idler roller:

Series 60.., 62.., 63.., Open/ ZZ/2RS..

6200 Series - Light Series Ball Bearings – Balanced between space and load capacity

6300 Series - Medium Series Ball Bearings – Ideal for heavier load capacity applications

To be the first class, to do the best quality, to make users satisfied, to ensure customers relieved, are our enterprise purposes. Welcome bearing dealers` and Conveyor Idler manufacturers contact from all over the world, and become our partner.